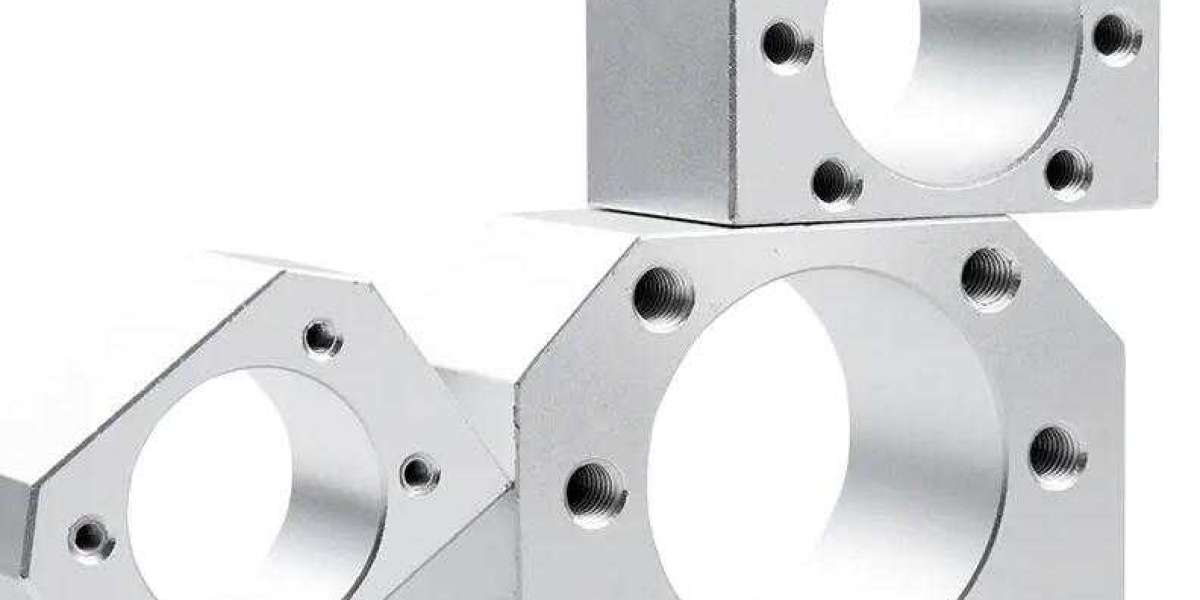

Ball Screw Nut Bracket are essential components in numerous industrial applications, facilitating efficient and precise linear motion. This article highlights some common areas where these brackets are utilized.

CNC machining centers heavily rely on ball screw nut brackets to support the movement of cutting tools and workpieces. The brackets ensure stability and accuracy, crucial for manufacturing intricate components. Similarly, in robotics, these brackets play a pivotal role in enabling precise positioning of robotic arms, contributing to advanced automation systems.

Another prominent application is in medical equipment, such as imaging devices and surgical robots. Ball screw nut brackets help achieve the precise and smooth motions necessary for these sensitive applications. In the automotive sector, they are used in assembly lines to handle repetitive tasks with high accuracy.

Packaging machinery also benefits from the integration of these brackets, ensuring consistent operation in high-speed environments. Their versatility allows them to adapt to different setups, making them indispensable across various industries.

https://www.hyballscrew.com/product/ball-screw-nut-seat/dsg-large-lead-nut-holders.html

Ball Screw Nut Seat widely used in industrial area.

Feature:

1. Space saving nternal circulate design

2. Low friction force with 1/3 over acme screw

3. Ensure for high accuracies

4. Micro feed with tolerance within 0.1μm

5. Zero backlashes, high stiffness.

Application:

For delicate application in industrial application, machine tool and automation application.