Welcome to the world of Expanded Polystyrene (EPS), a polymer with boundless versatility across industries. In construction, EPS reigns supreme for its remarkable insulation properties, resistance to pests and bacteria, and minimal water absorption. It serves as a key player in building elements, from insulated panels for facades to flotation material for marinas.

In food packaging, EPS proves its adaptability by being molded into trays for fruits and vegetables, ensuring freshness with its non-nutritive composition that deters microbial Join us as we explore the range of applications of EPS, from enhancing construction efficiency to preserving the freshness of our daily produce and safeguarding fragile goods along their journey. We will also throw light on the manufacturing process used for the production of EPS.

Introduction

Expanded Polystyrene (EPS) is a white foam plastic material, consisting of solid beads of Polystyrene, primarily used in packaging and construction. It is a closed-cell, rigid foam produced from styrene, which forms the cellular structure, and pentane, serving as a blowing agent. Comprising 98% air, EPS is highly recyclable and exceptionally lightweight. Its notable attributes include low thermal conductivity, minimal moisture absorption, and superior cushioning properties. With physical properties stable within a service temperature range of up to 167°F/75°C, EPS exhibits chemical resistance comparable to Polystyrene. EPS remains a versatile and widely utilized material across various industries, offering solutions for insulation, protection, and structural support. Also, Expanded Polystyrene, identified by plastic resin code 6, is entirely recyclable.

Here's a breakdown of the key features that make EPS so valuable in the world of polymers:

- Energy Efficiency: Building on the high R-Value, EPS products translate to significant energy savings. By keeping your desired temperature (hot or cold) contained within a space, you can rely less on heating or cooling systems, leading to lower energy bills.

- Constant Thermal Resistance: Unlike some insulation materials, EPS maintains its insulating properties consistently over time.

- Strength: Don't be fooled by its lightweight nature! EPS is surprisingly strong and can withstand significant compression and impact. This makes it suitable for various applications where structural integrity is important.

- Recyclability: EPS can be recycled multiple times throughout its life cycle, and its manufacturing process does not generate any leftover solid waste.

- No Bacterial Growth or Decay: EPS is resistant to mold, mildew, and bacteria growth. This makes it ideal for applications where hygiene is a concern, especially in food packaging and construction materials.

- Dimensional Stability: EPS maintains its shape and size over time, ensuring consistent performance and long-lasting functionality.

- Chemical Inertness: EPS doesn't react with most chemicals, making it a safe and reliable material for use in various settings.

- Low Cost: Compared to many other insulation materials, EPS offers excellent value for money. This affordability makes it an attractive option for a wide range of applications.

Manufacturing Process

Here's a breakdown of the key points involved in the manufacturing of EPS:

Expanded Polystyrene (EPS) foam is derived from expandable polystyrene (EPS) beads, a rigid cellular plastic containing an expansion agent sourced from oil. The EPS manufacturing process is closely linked to the process described previously, which traced the journey from oil extraction to the creation of expandable polystyrene. Now, let's delve into the transformation process leading to the production of EPS foam parts. The raw material, obtained through a chemical process, undergoes a series of physical transformations in three stages.

- Firstly, in the pre-expansion stage, the raw material (beads) is heated in specialized machines known as pre-expanders using steam at temperatures around 215°F. This causes the material's density to decrease from approximately 40 lbs/cu ft to typically between 1 to 2 lbs/cu ft. During pre-expansion, the solid beads transform into cellular plastic beads with small closed cells that trap air inside.

- In the second stage, intermediate maturing and stabilization, the recently expanded particles cool down, forming a vacuum within. This vacuum is compensated for by air diffusion, enhancing the beads' mechanical elasticity and expanding capacity. This stage occurs during the material's intermediate maturing in aerated silos or mesh bags, where the beads are simultaneously dried.

- Finally, in the third stage, expansion and final molding, the stabilized pre-expanded beads are transported to molds where they are exposed to steam once again, causing them to fuse together. This process yields large blocks through "block molding" (later cut into desired shapes like boards, panels, cylinders, etc.) or directly produces products in their final finished form through "shape molding."

Here is the production process used by INEOS, one of the leading producers of EPS on a global scale. INEOS Technologies provides cutting-edge expandable polystyrene (EPS) technology, offering a combination of competitive variable costs, low investment expenses, and a diverse range of high-quality products widely accepted globally. The demonstrated operational reliability of the process presents a significant competitive edge over other expandable polystyrene producers for upcoming projects.

In the production phase, a reactor is employed to catalyze the polymerization of styrene by introducing a specific blend containing blowing agents, water, initiators, suspending agents, and various additives. This complex mixture undergoes controlled temperature-time conditions with continuous stirring to ensure the dispersion of the monomer and the formation of Polystyrene beads. The entire process is managed by a Distributed Control System (DCS) following an automated sequence.

After polymerization, the resulting Polystyrene beads and water are transferred to a slurry tank, where the subsequent steps become fully continuous. This involves centrifugation to remove a significant portion of the suspension water, followed by conveying the beads to a pneumatic flash dryer to eliminate surface moisture. The dried beads undergo screening, resulting in the extraction of two specific product cuts out of a potential four. The effectiveness of this separation is enhanced by the presence of mineral suspension.

The precise segmentation achieved through this process allows for tailored targeting of product cuts to meet market demands. Typically, finer to medium cuts serve the packaging market, while medium to larger cuts are directed towards insulation applications.

Source: INEOS Technologies

Main Applications of Expanded Polystyrene

- Food Packaging

EPS can undergo extrusion using standard equipment to create a continuous sheet, which can then be shaped through vacuum forming and pressure forming processes to manufacture items like fruit trays. Devoid of any nutritional value, EPS effectively inhibits the growth of fungi, bacteria, and other microorganisms. Its thermal insulation properties play a pivotal role in preserving the freshness of food and preventing condensation across the distribution chain. Widely employed in food packaging, EPS serves as a protective medium for seafood, fruits, and vegetables. Furthermore, it is utilized in the production of food service containers such as drink cups, food trays, and clamshell containers, offering versatility and practicality in various culinary settings.

- Construction:

EPS finds extensive application in various structural components of buildings, including walls, roofs, and floors, where its compressive strength can be customized to suit specific construction systems such as beam and block setups, underfloor heating installations, and beneath concrete floor slabs. Additionally, it is utilized for void filling purposes and, when densified, serves as a suitable base material for road or rail embankments, particularly in scenarios where traditional fill materials prove excessively heavy. Notably, in urban areas, EPS offers the advantage of alleviating congestion and traffic by facilitating the efficient delivery of large quantities of product compared to conventional hardcore materials.

- Industrial Packaging

EPS ensures the comprehensive safeguarding of industrial products during transportation and handling, thanks to its remarkable shock absorption capabilities. This rigid yet lightweight foam can be molded into various shapes to effectively protect and insulate sensitive items, ranging from delicate medical equipment and electronic components to toys and horticultural products during storage and transit. Additionally, EPS finds utility in crafting disposable foam coolers and packing peanuts for shipping purposes. In packaging applications, the selection of appropriate cushioning levels depends on the packaging density to ensure optimal protection.

Market Outlook:

The Expanded Polystyrene (EPS) market is experiencing momentum from various factors, notably its diverse applications spanning construction, packaging, and insulation, leveraging its lightweight nature and excellent insulation capabilities. Particularly, the escalating demand for sustainable and energy-efficient construction materials propels EPS utilization in the building sector. In packaging, EPS's ability to provide protective cushioning proves advantageous, alongside its cost-effectiveness, recyclability, and ease of shaping, all contributing to its extensive acceptance. As environmental consciousness grows, the recyclability and sustainability aspects of EPS products emerge as pivotal drivers, resonating with worldwide initiatives toward eco-conscious solutions.

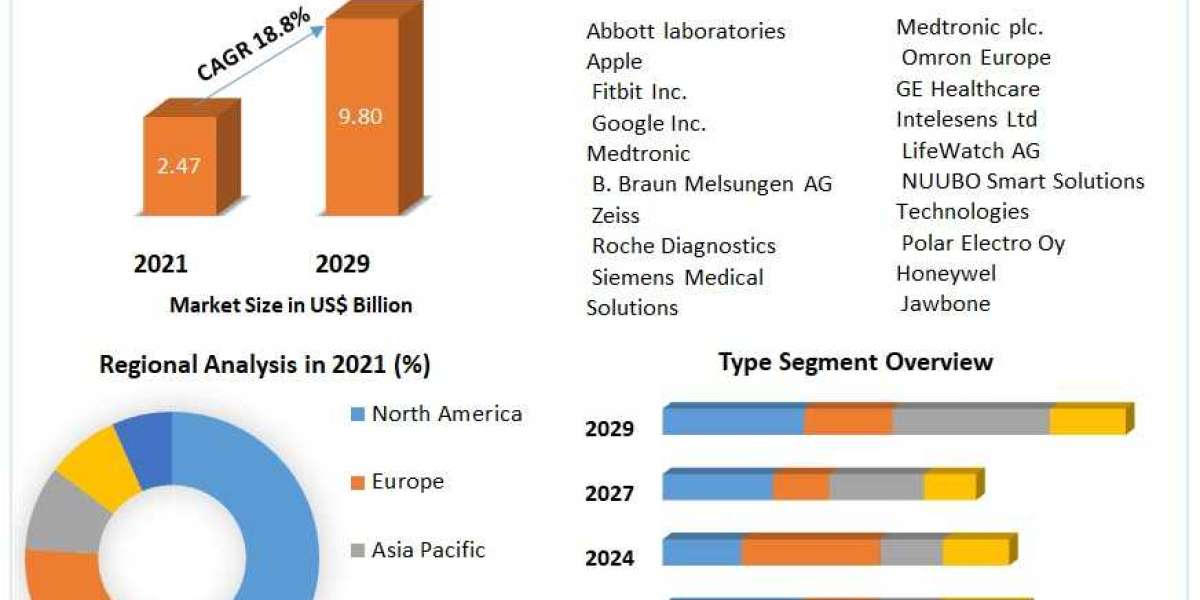

Expanded Polystyrene Main Players

Significant companies in the Global Expanded Polystyrene market are BASF SE, Atlas Roofing Corp., Alpek S.A.B. de C.V., Kaneka Corp., SIBUR Holding PJSC, BEWI, SUNPOR, Synthos, TotalEnergies, Flint Hills Resources, NOVA Chemicals Corporate, StyroChem, Ravago Manufacturing, UNIPOL, Versalis S.p.A., SABIC, Sundolitt Ltd, and Others.

Conclusion:

Expanded Polystyrene (EPS) is quietly revolutionizing the packaging industry with its impressive versatility. This lightweight champion is a favorite for its protective qualities, safeguarding products in sectors like industrial, food beverage, and electronics with its exceptional shock-resistance. Not only does EPS shield products from bumps, but its chemical-resistant nature and ability to inhibit bacterial growth ensure items stay safe from harmful interactions and unwanted microbes. Furthermore, EPS goes beyond protection - its insulating properties make it a cost-effective choice for cold storage, refrigerators, and construction applications, promoting temperature control and long-lasting durability. The future of EPS seems particularly promising, with the rapid urbanization driving demand for efficient packaging solutions in construction and consumer goods. As sustainability remains a top concern, ongoing advancements in EPS recyclability promise an even brighter future for this versatile and adaptable material.