Phenolic resin is a versatile synthetic polymer produced through the reaction of phenol and formaldehyde. It is valued for its excellent thermal stability, chemical resistance, and high mechanical strength, making it a staple material across various industries, including automotive, construction, electronics, and aerospace. Used in applications like molding compounds, adhesives, insulation materials, and laminates, phenolic resin has a steady demand in sectors focused on durable and heat-resistant materials.

Understanding the Phenolic Resin Price Trend is essential for industries relying on it for high-performance applications. This article examines recent trends in phenolic resin pricing, analyzes factors influencing price fluctuations, and provides insights into the potential outlook for the phenolic resin market.

1. Overview of the Phenolic Resin Market

Market Demand and Applications

The global phenolic resin market has experienced steady growth, driven by demand across key industries:

- Automotive: Used in brake pads, clutches, and insulation parts due to its heat resistance and durability.

- Construction: Used in laminates, insulation, and adhesives, especially for applications requiring fire-resistant materials.

- Electronics: Applied in circuit boards, insulation materials, and as a component in fire-resistant coatings.

- Aerospace: Valued for its stability under extreme temperatures, making it useful in aircraft components.

Major Producers and Consumers

The Asia-Pacific region, particularly China, leads in phenolic resin production and consumption, followed by North America and Europe. Growing infrastructure projects, increasing automotive production, and rising demand for consumer electronics contribute to the phenolic resin market’s expansion in these regions.

Enquire For Regular Prices: https://www.procurementresource.com/resource-center/phenolic-resin-price-trends/pricerequest

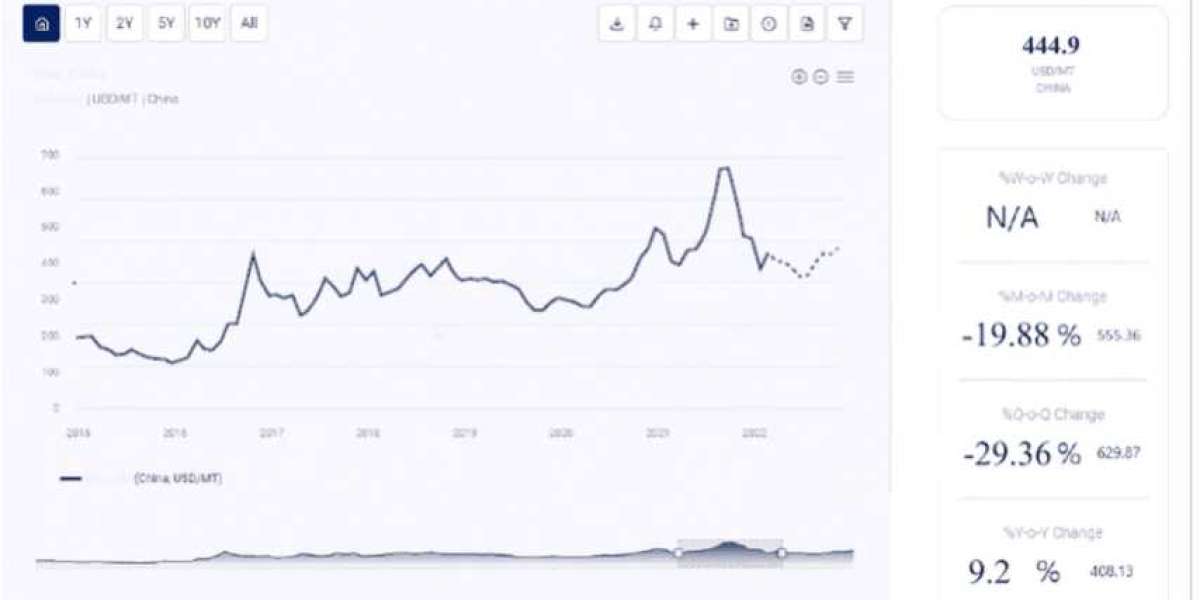

2. Historical Price Trends of Phenolic Resin

The price of phenolic resin has been influenced by raw material costs, particularly phenol and formaldehyde, as well as the global supply-demand balance. Key historical price trends include:

Early 2010s to Mid-2015: Steady Growth

During this period, the phenolic resin market grew steadily due to increased demand from construction and automotive sectors. Raw material prices remained relatively stable, contributing to a steady cost structure for phenolic resin.

2016 to 2019: Rising Costs from Raw Material Volatility

Rising prices of phenol, driven by fluctuations in crude oil prices, led to increased production costs for phenolic resin. The automotive and construction boom in emerging economies also spurred demand, adding upward pressure on prices.

2020 to Present: Pandemic Impact and Supply Chain Disruptions

The COVID-19 pandemic affected phenolic resin prices due to disruptions in supply chains and fluctuations in demand across key industries. While there was reduced demand initially, the market rebounded quickly with the recovery in automotive and construction sectors, leading to price volatility driven by supply shortages and increased freight costs.

3. Factors Influencing Phenolic Resin Prices

Phenolic resin prices are affected by multiple factors, including raw material costs, production efficiency, regulatory trends, and market demand.

a) Raw Material Costs: Phenol and Formaldehyde Pricing

Phenol and formaldehyde are petroleum-based raw materials, making phenolic resin prices susceptible to fluctuations in crude oil prices. Phenol prices are especially volatile, given its use in other industries like epoxy resins and bisphenol-A production, leading to high competition for supply. The formaldehyde market, influenced by methanol prices, also affects phenolic resin costs. Any changes in these raw material markets can significantly impact phenolic resin pricing.

b) Demand from End-User Industries

Automotive, construction, and electronics sectors are the largest consumers of phenolic resin. Economic growth in these industries drives demand, impacting prices. For instance, increased automotive production raises the demand for phenolic resin in brake pads, while construction growth boosts demand for insulation and laminates. Conversely, slowdowns in these sectors, as seen during the pandemic, tend to ease demand pressure on prices.

c) Production Costs and Technological Advances

The production process for phenolic resin requires specific chemical reactions and energy inputs. Advances in production technology have improved efficiency, allowing for cost savings in some cases. However, meeting higher quality standards and adopting cleaner, more efficient production methods can raise operational expenses, impacting resin prices.

d) Environmental and Regulatory Factors

Regulations governing formaldehyde emissions have become increasingly stringent, impacting phenolic resin production. Manufacturers are investing in low-emission or emission-free formulations to meet environmental standards, which may raise production costs. Regulations on workplace safety and handling of chemicals also affect production expenses, adding upward pressure on prices.

e) Supply Chain and Transportation Costs

The global supply chain crisis in recent years has affected phenolic resin prices. High transportation costs and delays in raw material shipments have led to supply constraints. Regional disruptions, including trade tariffs and port congestions, further exacerbate price volatility, especially in regions reliant on imported raw materials.

4. Regional Analysis of Phenolic Resin Prices

Asia-Pacific

Asia-Pacific is the largest producer and consumer of phenolic resin, with China leading the market due to its robust construction and electronics sectors. The region benefits from cost-efficient production capacities, but recent environmental regulations in China have increased compliance costs for manufacturers, influencing local prices.

North America

North America, with its established automotive and aerospace industries, maintains steady demand for phenolic resin. Prices in this region are influenced by domestic production capacities and trade policies, especially concerning raw materials. The U.S. market has also experienced price fluctuations from regulatory changes targeting formaldehyde emissions.

Europe

Europe’s phenolic resin market is characterized by stringent environmental regulations, which add to production costs. Demand is driven by the automotive and construction industries, but recent shifts toward electric vehicles (EVs) could reduce phenolic resin demand in brake components over time. European producers face higher costs due to regulations, making phenolic resin prices relatively higher in this region compared to Asia.

5. Future Outlook for Phenolic Resin Prices

a) Demand Growth in Construction and Infrastructure

The global construction industry is expected to grow as urbanization and infrastructure projects increase, especially in emerging economies. This growth is likely to boost demand for phenolic resin in insulation and laminates, leading to potential price increases due to higher demand.

b) Advancements in Automotive and Electronics Applications

With the rise of EVs and smart devices, the demand for high-performance, fire-resistant materials is likely to grow. Phenolic resins are well-suited for applications requiring heat resistance and durability, which could sustain demand growth in automotive and electronics sectors. However, shifts towards alternative materials may gradually affect demand in specific automotive applications.

c) Environmental Regulations and Sustainable Alternatives

Increasingly stringent environmental regulations will drive producers to innovate with lower-emission phenolic resins. Research into bio-based phenolic resins offers an alternative, albeit at a higher cost. While such sustainable options may mitigate environmental impact, they could result in higher prices until production scales up to achieve cost efficiency.

d) Supply Chain Stabilization and Regional Self-Sufficiency

Efforts to strengthen domestic supply chains and reduce reliance on imports are expected in many regions, especially following recent disruptions. Improved supply chain resilience could help stabilize phenolic resin prices by mitigating risks from global transport costs and import tariffs. However, building these capabilities may lead to short-term cost increases.

6. Strategies for Managing Phenolic Resin Costs

Companies relying on phenolic resin for their manufacturing processes can employ several strategies to manage costs effectively:

Diversifying Suppliers: Working with multiple suppliers or regions can help reduce risks from regional price fluctuations and ensure a stable supply.

Investing in Sustainable Alternatives: Researching and adopting bio-based or recycled phenolic resins could help companies meet regulatory requirements while supporting sustainability goals, though initial costs may be higher.

Enhancing Production Efficiency: Companies that produce phenolic resin can improve their cost efficiency through energy-efficient technologies and optimized production processes.

Recycling and Circular Economy Initiatives: Implementing recycling initiatives for phenolic resin in certain applications could reduce demand for raw materials and manage waste, supporting long-term cost savings.

Phenolic resin is a critical material across multiple industries, from automotive to construction and electronics. Its price trends are driven by a combination of raw material costs, end-user demand, technological advancements, and environmental regulations. While phenolic resin prices have experienced volatility due to supply chain disruptions and rising raw material costs, future demand remains strong, supported by infrastructure growth and the demand for high-performance materials in emerging applications.

In response to regulatory pressures and sustainability goals, the market may witness a gradual shift towards bio-based phenolic resins and recycling initiatives, though these changes could lead to higher production costs initially. For manufacturers and consumers of phenolic resin, understanding these trends and adapting to market changes will be crucial for maintaining a competitive edge in the years ahead.

Contact Us:

Company Name: Procurement Resource

Contact Person: Leo Frank

Email: sales@procurementresource.com

Toll-Free Numbers:

- USA Canada: +1 307 363 1045

- UK: +44 7537171117

- Asia-Pacific (APAC): +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA