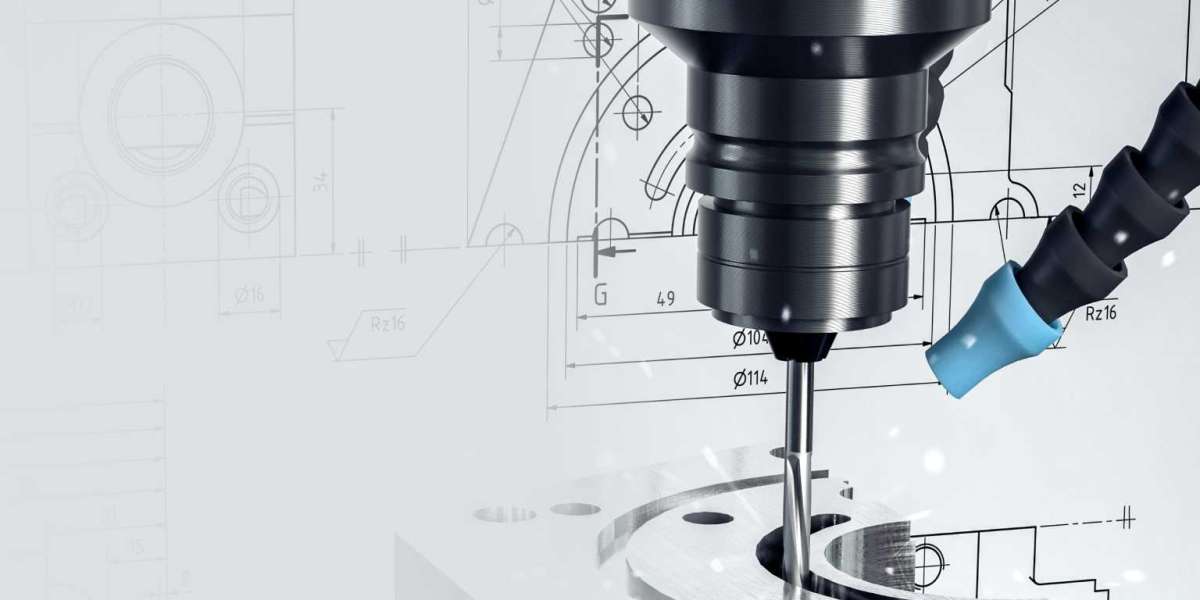

In the world of manufacturing, speed, precision, and cost-effectiveness are key to staying competitive. CNC prototype machining has become an indispensable tool in the product development process, offering companies the ability to quickly and accurately produce prototypes of parts and components. By utilizing Computer Numerical Control (CNC) technology, this process allows manufacturers to create functional models directly from digital designs. This article explores the significance of CNC prototype machining, how it works, its advantages, and its diverse applications across industries.

What is CNC Prototype Machining?

CNC prototype machining is a manufacturing process that uses CNC machines to create prototypes from a 3D CAD (Computer-Aided Design) file. These prototypes are produced by cutting, milling, drilling, and shaping raw materials into the precise specifications needed for testing and evaluation. CNC machines are programmed with G-code instructions, which dictate the movements and operations of the machine tools.

What sets CNC prototype machining apart from other prototyping methods is its ability to create accurate, functional, and highly detailed prototypes in a relatively short amount of time. The result is a physical model that can be tested, evaluated, and modified as needed, streamlining the design process before mass production.

The CNC Prototype Machining Process

The process of CNC prototype machining is relatively straightforward but involves several key steps:

1. CAD Design and Model Creation

The first step in CNC prototype machining is designing the part or product in CAD software. Engineers and designers create a 3D model of the prototype, specifying all relevant dimensions, tolerances, and material properties.

2. CAM Programming

Once the design is completed, it is imported into CAM (Computer-Aided Manufacturing) software. The CAM software generates the tool paths and G-code that tells the CNC machine how to move and what actions to perform to create the part.

3. Machining the Prototype

The CNC machine then uses the instructions from the G-code to begin the machining process. The machine precisely cuts, mills, drills, or shapes the raw material into the desired form, layer by layer. Depending on the part’s complexity, multiple machining processes may be involved.

4. Post-Processing

After machining, the prototype may require post-processing steps like deburring, sanding, polishing, or coating to improve its surface finish, appearance, and functionality. These finishing steps ensure that the prototype meets the required specifications.

5. Testing and Refining

Once the prototype is complete, it can be tested for fit, function, and durability. Feedback from testing is used to refine the design, and the process can be repeated to create additional prototypes with updated features or improvements.

Key Benefits of CNC Prototype Machining

CNC prototype machining offers numerous advantages that make it a preferred choice for modern product development. Below are some of the most significant benefits:

1. Rapid Prototyping

One of the most significant advantages of CNC prototype machining is speed. The process is incredibly fast, allowing manufacturers to produce prototypes in a matter of hours or days, depending on the complexity of the design. This rapid prototyping capability allows companies to evaluate designs early and make quick adjustments, shortening product development cycles and accelerating time-to-market.

2. Precision and Accuracy

CNC machines are known for their high precision and accuracy. They can produce prototypes with tight tolerances, ensuring that each part matches the digital design with incredible accuracy. This is particularly crucial for industries that demand high standards, such as aerospace, medical, and automotive sectors.

3. Material Versatility

CNC prototype machining supports a wide variety of materials, including metals (aluminum, steel, titanium), plastics, composites, and even wood. This material flexibility enables manufacturers to produce prototypes that closely match the intended production materials, allowing for realistic testing and evaluation of the part's properties.

4. Cost-Effectiveness for Low-Volume Production

Unlike traditional manufacturing methods, which often require expensive molds or tooling, CNC prototype machining is cost-effective for low- to medium-volume production. There are no tooling costs, which makes it ideal for producing a small number of prototypes or iterating through different designs without a huge financial commitment.

5. Design Flexibility

CNC prototype machining offers the flexibility to make changes to the design quickly and easily. Because the process is driven by digital models, modifications can be made to the CAD file, and the prototype can be re-machined without significant delays or costs. This iterative design process is valuable in refining prototypes and improving functionality before moving to full-scale production.

6. Capability for Complex Geometries

CNC machines are capable of producing parts with complex geometries, including intricate curves, fine details, and multi-axis shapes. Multi-axis CNC machines can produce parts that would be impossible to create using traditional methods, allowing for greater design freedom and innovation.

Applications of CNC Prototype Machining

CNC prototype machining is widely used across various industries, enabling manufacturers to create functional prototypes for testing and validation before committing to full-scale production. Some of the key applications include:

1. Aerospace

In aerospace, prototypes must meet extremely high standards of performance, safety, and precision. CNC prototype machining is used to create complex components, such as turbine blades, structural brackets, and engine parts. Prototypes are tested for aerodynamics, strength, and durability, ensuring that they meet rigorous industry standards.

2. Automotive

Automotive manufacturers rely on CNC prototype machining to produce prototypes of components like engine parts, chassis components, and interior features. These prototypes are subjected to testing for fit, performance, and safety. CNC machining allows for rapid iteration of designs, making it easier to refine components and optimize functionality before moving to mass production.

3. Medical Devices

The medical industry demands the highest level of precision and reliability in product development. CNC prototype machining is essential for creating prototypes of medical devices, such as surgical instruments, implants, and diagnostic tools. These prototypes are tested for biocompatibility, usability, and performance, ensuring that the final product meets stringent regulatory standards.

4. Consumer Electronics

Consumer electronics, such as smartphones, wearables, and home appliances, often require prototypes for testing design, fit, and function. CNC prototype machining allows manufacturers to quickly produce functional prototypes of casings, connectors, and internal components to ensure that the design meets consumer expectations and performs as intended.

5. Industrial Equipment

CNC prototype machining is also used in the development of industrial equipment parts, including gears, valves, actuators, and machinery components. Prototyping these parts ensures that they are functional, durable, and reliable before being used in heavy-duty applications.

6. Product Design and Development

Beyond specific industries, CNC prototype machining is frequently used in product design and development for a variety of consumer products, industrial tools, and engineering systems. Designers can create realistic prototypes of their concepts, allowing them to visualize the final product and make necessary adjustments before mass production.

CNC Prototype Machining vs. Other Prototyping Methods

While other prototyping methods such as 3D printing, injection molding, and casting are also commonly used, CNC prototype machining offers some distinct advantages:

3D Printing: While 3D printing is ideal for quick, inexpensive prototypes, it often lacks the material strength and precision of CNC-machined parts. CNC machining provides higher-quality finishes and works with a broader range of materials, including metals, which 3D printing cannot achieve as effectively.

Injection Molding and Casting: These methods are suited for large-scale production but involve high initial setup costs for tooling and molds. CNC prototype machining, on the other hand, is more flexible for low-quantity production and iterative design changes without the need for expensive tooling.

Manual Machining: Traditional manual machining is slower and less precise than CNC machining. While manual machining can still be useful for simple parts, CNC machines offer higher accuracy and can produce complex shapes with far greater efficiency.

Challenges and Considerations

Despite its many benefits, CNC prototype machining does come with some challenges. Complex prototypes may require multi-axis CNC machines, which can be more expensive to operate. Additionally, the programming and setup process can take time, which may increase costs for simple prototypes. However, these challenges are typically outweighed by the significant advantages that CNC machining offers in terms of precision, speed, and flexibility.

Conclusion

CNC prototype machining is a powerful tool that has revolutionized the product development process. Its ability to quickly produce accurate, high-quality prototypes allows manufacturers to iterate designs faster, reducing time-to-market and minimizing costly mistakes. From aerospace to consumer electronics, CNC prototype machining has become an essential technology in industries where precision and performance are critical. By offering speed, flexibility, and precision, CNC prototype machining enables manufacturers to bring their innovative ideas to life with greater efficiency and accuracy. As technology continues to evolve, CNC machining will remain a cornerstone of modern manufacturing.